How does single-phase induction motor works?

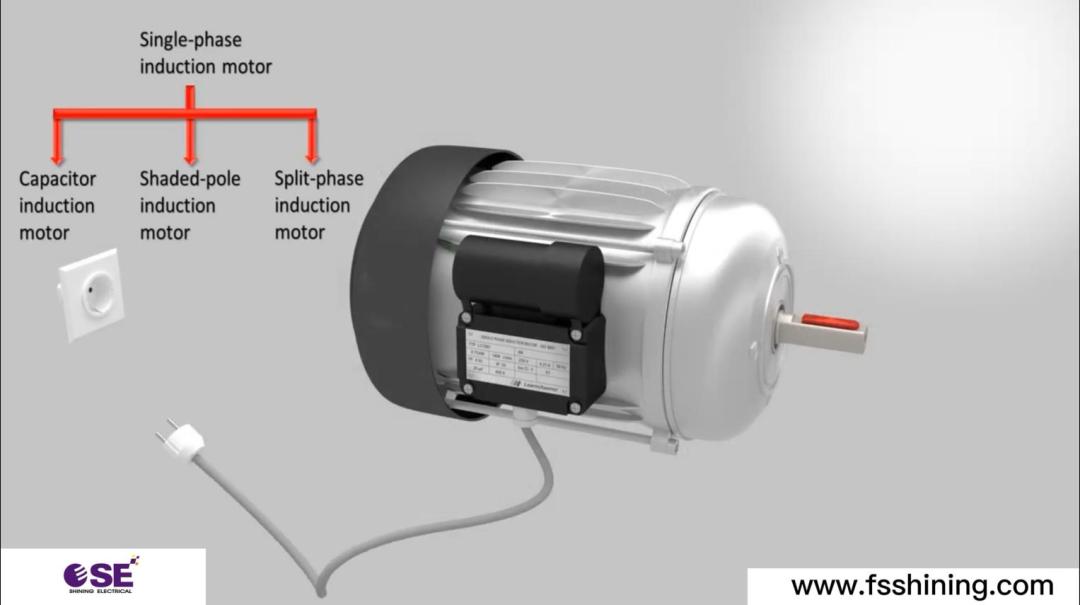

In our daily life, we use electric appliances as a matter of course. Well – these devices shown here use a single-phase induction motor. But how does this motor work. Once we plug it into the socket? What are its advantages and disadvantages? After this article, you will have a better idea!

When talking about the single-phase induction motor,you usually mean the capacitor motor. In this article, we confine ourselves to the capacitor motor. The function of this motor is very similar to the function of the three-phase induction motor.

To understand the capacitor motor, you should first understand how a rotating magnetic field, or RMF, can be built with only one single phase.

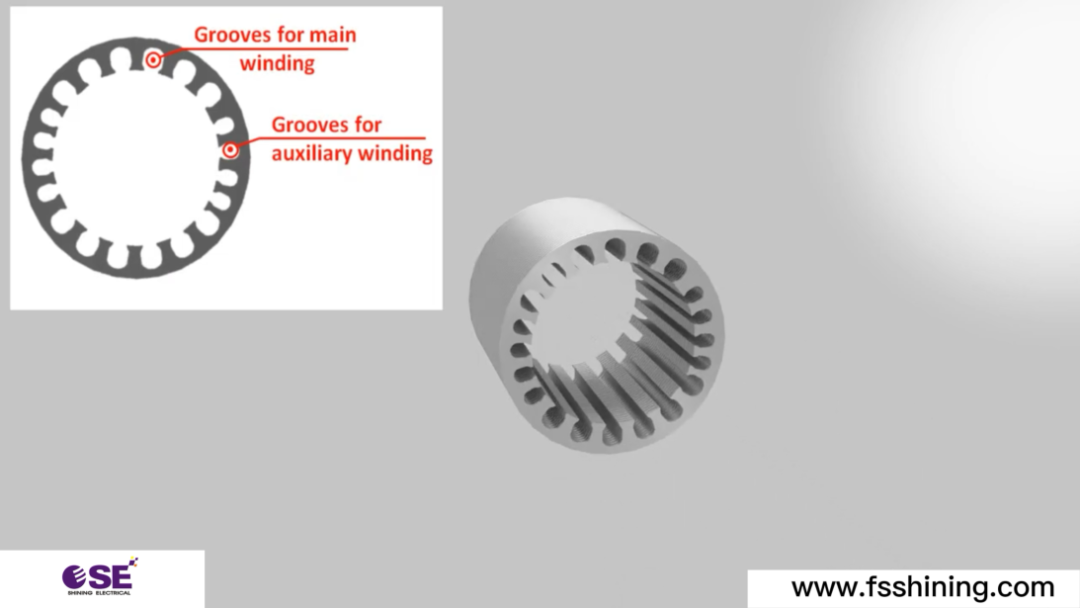

The stator consists of a hollow, cylindrical corewith a number of evenly spaced slots, which provide the space for the stator

winding.

To interrupt the path of the electric eddy currents,this core is made up of stacked laminations.So let's place a winding within the stator and connect this to an AC power supply. What you see is an alternating magnetic field. But to give the motor a starting torque as well as a defined sense of rotation, we need a rotating magnetic field.

So how do we create one?

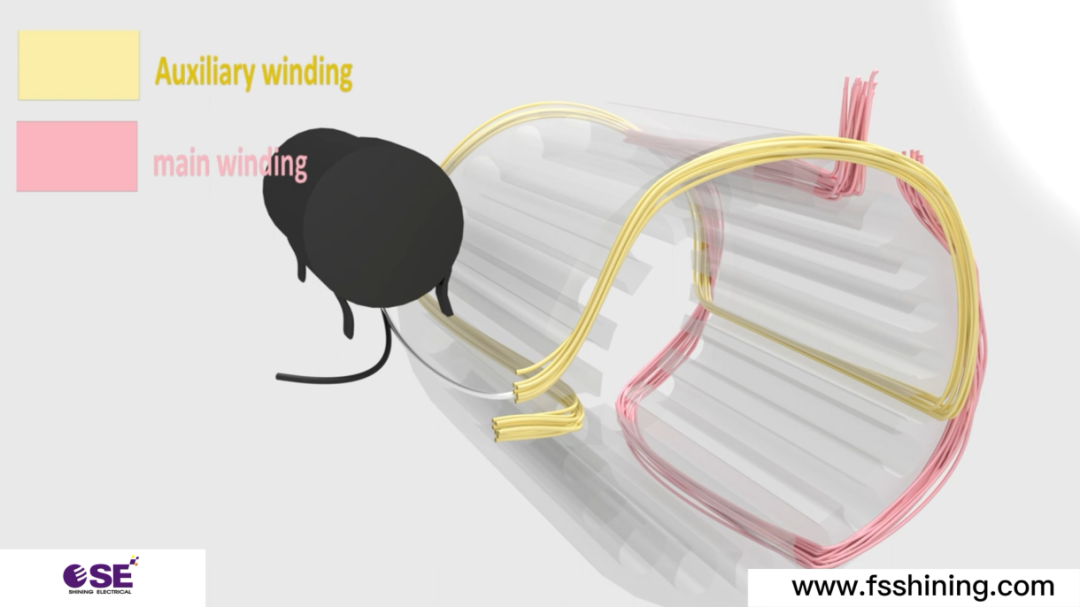

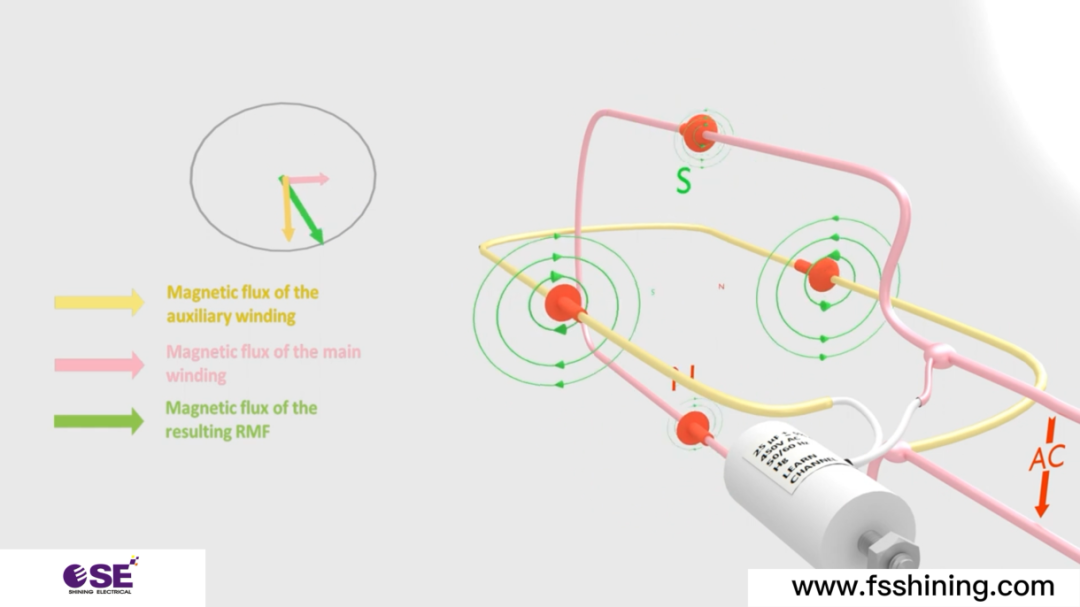

One possibility to get to an RMF is to create a second,so-called auxiliary winding, displaced by 90 degrees to the primary winding. Furthermore, the current in this auxiliary winding is almost 90-degrees out of phase.

You get this phase shift by connecting a capacitor in series. Now it's time to switch to another view for better understanding.

Due to the capacitor,the magnetic flux of the auxiliary winding is perpendicular to the flux of the main winding.Adding these two fluxes together,you get the resulting magnetic flux. And you get a rotating magnetic field.

Because the main winding is about 2/3 of the total winding,the resulting RMF is elliptical.

Here is an RMF with two poles. Of course, you can also build an RMF with four or more poles. Look at the inside of the motor. As you learned, the RMF is built within the stator. The rotor, the moving part of the motor, consists of bars with end caps on each side. Therefore, you can also call this motor a "squirrel cage motor."To enhance the magnetic field of the rotor, and therefore the torque,the rotor bars are mounted within a pack of steel laminations.

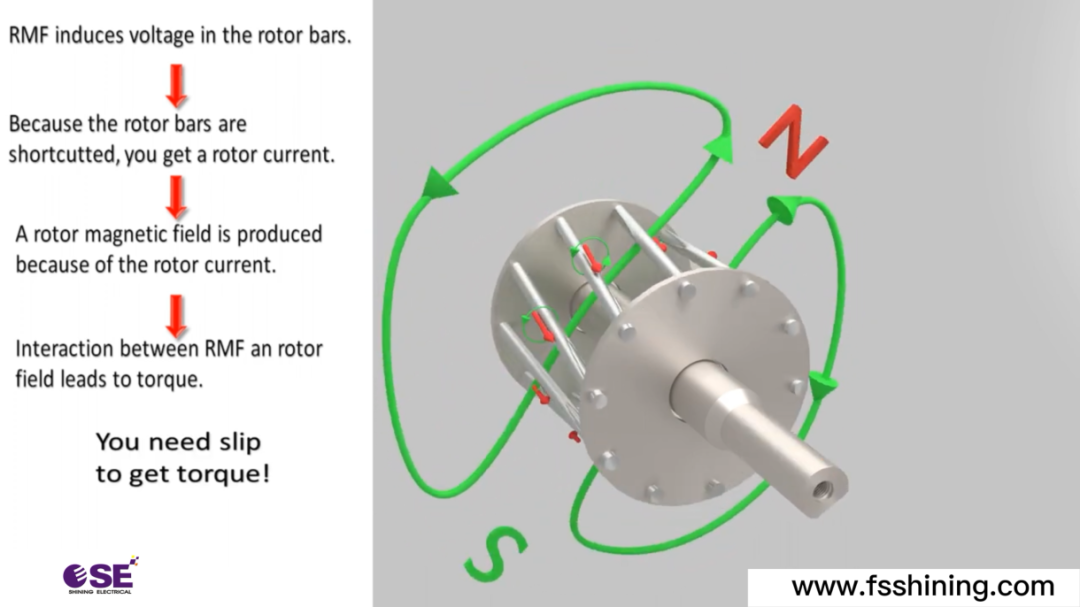

As the stator magnetic field rotates, voltage is induced within the bars of the rotor. As the rotor bars are shorted at both ends, there is a closed path for the flow of current.

Produces a magnetic field in the rotor bars, which opposes the magnetic field of the stator. The direction of the force as a result of the interaction between stator and rotor field can also be determined by the Lorentz Law.

Why slip?Torque can only be created when the rotor current is induced. To say it in other words,the rotor always has a rotating speed less than the RMF. This difference is called "SLIP." The function of a single-phase

induction motor is very similar to the function of a three-phase motor.

So the characteristic curves are also similar. Several effects determine this curve,and you can mark the distinctive points. The problem with this motor is its low starting torque.With a simple trick, you can provide a starting boost. Add another bigger capacitor in series to the auxiliary winding.

Due to overheating, this starting capacitor must be switched off at a certain speed by a centrifugal switch. Once the induction motor has reached its nominal range, it can maintain its nominal speed quite well, even with a varying load. That's because the torque curve is deepest at the nominal point.

Watch three-phase induction motors! To change the sense of rotation of the motor, the current direction within the auxiliary winding must be reversed.

If the manufacturer offers an AC motor with a six-pin motor terminal board,you have a very easy task to change the sense of rotation. Just replace the metal jumpers as indicated by the diagram! All values refer to rated operation.

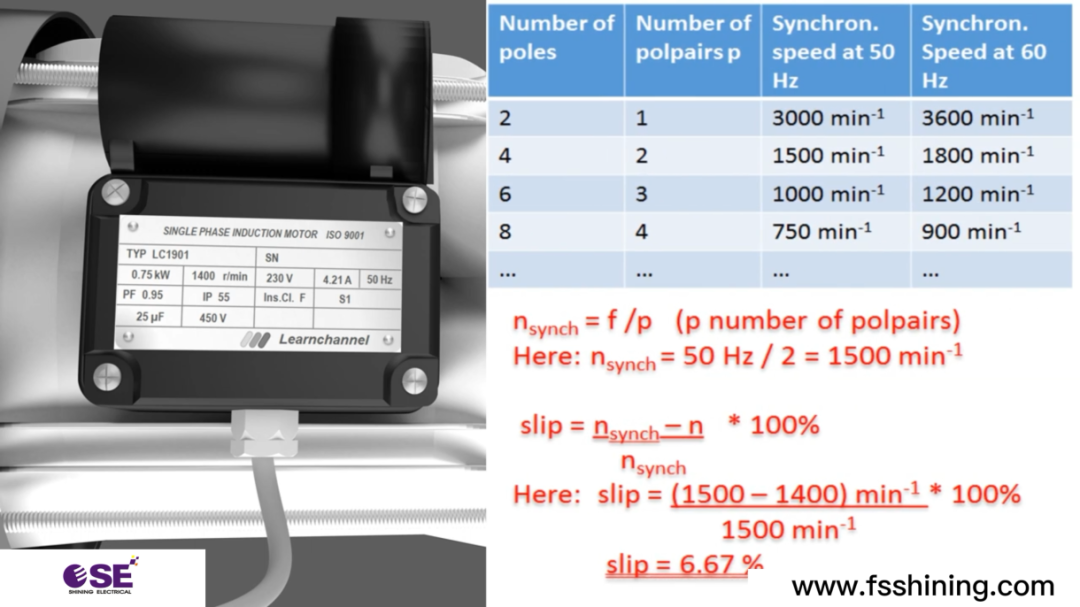

In rated operation,an induction motor has the best ratio of efficiency to power factor.The slip in rated operation is approximately between three and seven percent. This motor has a nominal speed of 1400 RPM. With this information, you can evaluate the synchronous rotational speed of the RMF and, furthermore, the slip.

The power on the motor plate is the mechanical output power. The nominal torque can be calculated with a known equation. There exists a rule of thumb to determine the run capacitor: The capacity is between 30 microfarads and 50 microfarads per kW of motor power.

This is a very rough estimate. The reason is that the size of the capacitor depends on the motor power and the winding ratio of the working and auxiliary winding. It is very difficult to determine the capacitance. It is best to contact the manufacturer. The start capacitor, if it exists, is about three times as big as the run capacitor.

The rated input power or electrical power can now be determined by a simple equation. The efficiency is a simple ratio. The insulation class describes the thermal tolerance of the motor windings.

The letter indicates the motor winding's ability to withstand operating temperatures for a specific length of time.The code IP, or Ingress Protection, defines how well an enclosure protects against the external environment. As the number gets higher, the protection gets better.

The first digit defines the protection level against "solids," the second against "liquids." You must use both digits to define an enclosure. Further information about your motor can be obtained from the datasheet.

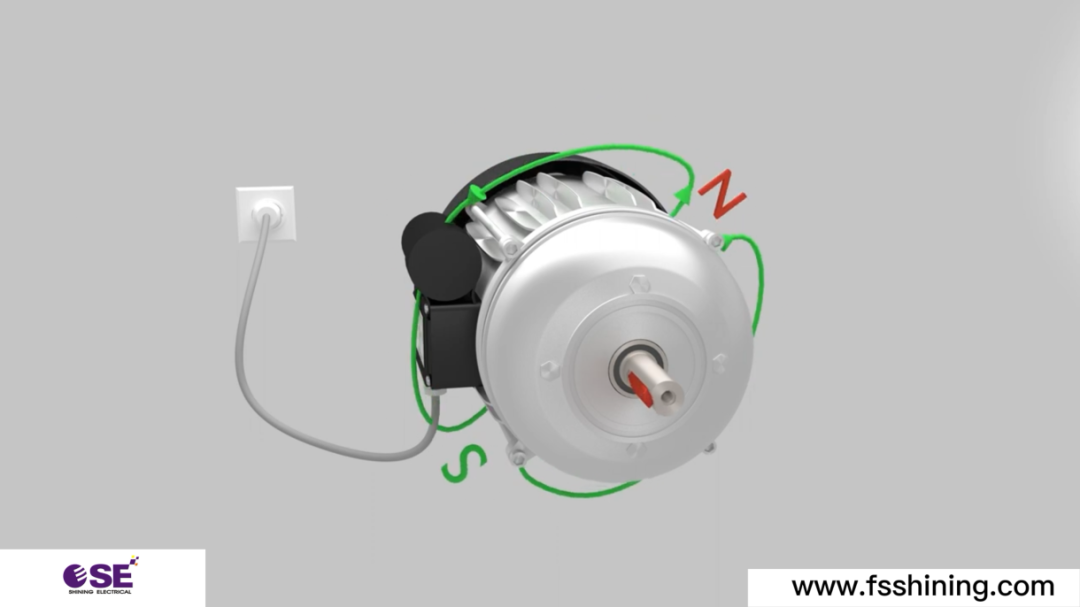

The capacitor motor can be classified as asynchronous, AC, and induction motor. It is a rather robust motor, but the weak point is the capacitor and the speed switch if you have a starting capacitor.

Because electronics are becoming more and more powerful and cheap,big single-phase induction motors are replaced more and more by three-phase induction motors controlled by VFD. You should know that small VFD can be connected to single-phase voltage.

If you are interested, welcome to contact us:

![]() WhatsApp: +86 13144118381

WhatsApp: +86 13144118381

![]() Email: operating@fsshining.com

Email: operating@fsshining.com

![]() Web: www.fsshining.com

Web: www.fsshining.com

Spain Retail Services: www.fswinstep.com

![]() Foshan Shining Electrical Appliance Co., Ltd.

Foshan Shining Electrical Appliance Co., Ltd.